- turn off the wiring by disconnecting the block from the harness;

- unscrew the left nut to turn off the engine;

- unscrew the screws securing the fan;

- we get a casing;

- remove the remaining bolts and the intake grille;

- raise the fan support and pull it toward you;

- turn the fan 90 ° and take it out.

- turn on the multimeter at 50-100 ohms;

- we check the paired conclusions on the collector: the resistance of all windings should be equal;

- the resistance between the collector lamellas and the housing is normally infinite;

- call stator windings;

- we check the case-output circuit of the windings for a breakdown.

- Service stations break a lot of money for simple computer diagnostics

- To find out the error you need to go to the experts

- Simple wrenches work in the services, but you can not find a good specialist

Original German Power Guard Auto BuffersAuto buffers - save money on suspension repairs, increase clearance by 3 cm, quick and easy installation ...

Official website \u003e\u003e\u003e

On the way, you noticed that the arrow of the liquid temperature indicator has exceeded the red mark and is moving steadily further. We urgently stop, raise the hood: it is - the fan blades are motionless. How to fix the breakdown and get home? Read more about this.

1 Radiator fans - purpose and design

The radiator cooling fan is used for air cooling, which, together with liquid, ensures the optimum temperature regime of the motor. To increase the efficiency of liquid cooling, a radiator is used: the oncoming air passes through its cells and cools the liquid. But at low speeds or in city traffic, the air flow is insufficient. To avoid overheating, a fan is turned on, which directs air to the radiator, cooling it.

On older models and modern SUVs with a longitudinally placed engine, a mechanical cooling fan drive is used. It works constantly with older cars, later they started installing a viscous coupling, which disconnects it if necessary. It is used on large trucks and SUVs. Advantages are that it is not afraid of water ingress, unlike electric fans.

Most cooling fans on modern cars have an electric drive. The system is simple - just three key elements: a 12-volt electric motor, an impeller on its shaft and electrical wiring. Fan operation is only necessary when the coolant temperature approaches critical and there is a risk of overheating.

To automatically turn on the cooling fan, a temperature sensor is provided. It measures the temperature of the coolant. When it is acceptable for normal motor operation, the fan is off. If there is a risk of overheating, a thermal switch sends a command to turn on the fan. When the temperature drops, the cooling fan is switched off by the sensor.

A more advanced, but also more complex fan control system - with an electronic control unit. In addition to the ECU, it includes a monitoring sensor - on modern machines, more often two. One is installed in the pipe exit from the radiator, the other - at the output of the power unit. The control unit module responsible for the cooling system responds to the difference in the readings of the two sensors. On some new models, it is possible to participate in the management of the cooling fan and other sensors that monitor the crankshaft speed, fuel consumption. All signals are supplied to the computer, which analyzes them and sends the desired command.

2 Fan does not work - troubleshooting

Malfunctions of cooling fans occur regardless of how they are connected and controlled. On cars with a mechanical fan drive, diagnostics are carried out visually. Electric systems using only a thermal switch are easily diagnosed. In the most modern systems, it is required to identify a faulty element among the device circuit. A problem with an idle fan can be hidden in the fuse box, any of the sensors, the computer, the motor itself.

If the fan does not start, start by checking the thermostat. This is done by hand: we try the bottom pipe of the radiator to the touch. If it is cold - the thermostat is not working, it jammed. The fluid moves in a small circle all the time, in the radiator it is cold, and in the engine it overheats. The temperature sensor located on the radiator detects a low liquid temperature and does not give a command to turn on the fan; thermostat needs to be replaced. Be careful when checking: you can get burned.

IT'S IMPORTANT TO KNOW!

Every motorist should have such a universal device for diagnosing his car. Now without an autoscanner just nowhere!

You can read, reset, analyze all sensors and configure the on-board computer of the car yourself using a special scanner ...

Particularly frequent breakdowns of the thermostat on cars Lada Kalina. Many of its owners are aware of this and take a spare with them or resort to radical measures: they replace the staff with a reliable 6-hole one.

We are convinced of the operability of the fan motor. We disconnect the standard wires from it, so as not to use various sensors, computers, and connect directly to the battery. A spinning fan tells you that the problem is elsewhere. Diagnose electrical wiring by eliminating individual elements. It does not interfere with inspecting the wiring, contacts. Sometimes it is enough to insulate damaged areas or clean contacts.

We check the fuse, which on most cars at the same time protects the horn circuit. We press the horn: if the signal does not work, we change the fuse. If the fuse is not to blame, we inspect the fan relay: wire integrity, insulation status, contacts. Turn it off and close the wiring to turn on the fan directly. If it works, the disconnected part is faulty, it should be replaced.

It was the turn to start checking the temperature sensor. We disconnect the connector and close the thermal switch contacts with a screwdriver. If the fan is working, the temperature sensor is faulty; if not, the engine or other parts of the circuit break down. Some models are equipped with a dual temperature sensor. The principle of verification is the same: we close one pair, then another. When the fan is running, its rotation speed will change. On injection engines, we simply remove the connector, the computer must turn on the emergency mode of the fan. If this happens - the temperature sensor is inoperative.

If the car is equipped with an on-board computer, which, in addition to many other functions, is responsible for the operation of the cooling fan, you should contact a car service. Check and repair the computer can only professionals using the appropriate equipment.

3 Troubleshooting - minor and major repairs

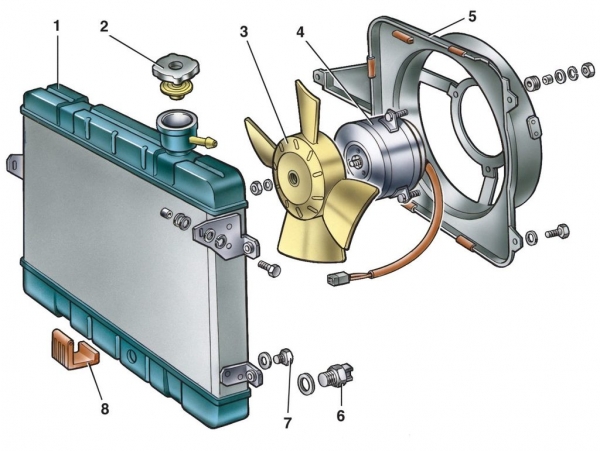

Failures of individual parts of the air cooling system are eliminated by replacement with new ones. If the fan does not turn on and you are convinced that the reason is in it, you should dismantle it in order to find out a specific breakdown. Depending on the complexity, it is either eliminated or the engine is replaced with a new one. Let's take as an example the dismantling of a fan on a VAZ-21099: the Samara family often suffers in the summer due to overheating.

Remove the fan:

We check the efficiency of the rotor, the condition of the windings. First, clean them with a brush and a rag with solvent. We call the windings with a tester:

If a winding malfunction is detected, it is better to buy a new fan motor, and not return the old one for repair.

We assess the condition of the collector assembly. The plates should be clean, nothing should be in between. On a scruffy engine, the manifold plates are dirty, with traces of graphite in the grooves. Worn brushes cause sparking due to the reduced pressure force on the lamellas. This causes increased wear on the brushes and the manifold, causing the engine to stop working. We remove the dirt with a cloth with a solvent, between the plates - pieces of solid non-resinous wood. We rub the brushes with sandpaper-nulevka. A collector with potholes, burnt areas is punched and polished.

4 Fault on the way - how to get home

It is better to repair a faulty fan at home, but if a breakdown occurs on the way and cannot be fixed, you can still get home on your own. When they found overheating in the devices due to an idle fan, we pull over to the side of the road and stop. We stop the engine, raise the hood to cool more quickly. We check the operation of the fan, as described above, or immediately connect the fan directly.

If it didn’t work even with direct connection, continue moving without a fan. We select a speed of at least 60 km / h so that the radiator is cooled by oncoming air without a fan. If the weather is not very hot or in winter you will be able to get home without problems. If there is heat, open the windows and turn on the heating: part of the heat will go into the cabin and it will be possible to travel a greater distance. We constantly look at the temperature of the coolant. If the coolant starts to overheat, stop and wait until it cools. It is better to arrive later than to overheat the engine.

It should be said that many owners of VAZs, especially classics, conclude in advance that the fan is turned off in the cabin. Apparently they do not want to deal with the cause of the breakdown or buy parts, do repairs. It is done very simply: a plus is supplied to the button through the standard fuse, from it - to the fan motor. The fan is already connected to ground.

Do you still think that diagnosing a car is difficult?

If you read these lines, then you have an interest in doing something yourself in the car and really save, because you already know that:

And of course, you are tired of throwing money away, and there is no way to drive around the service station, then you need a simple ELM327 AUTOSCANNER that connects to any car and you will always find a problem through a regular smartphone, pay off CHECK and save a lot of money! !!

We ourselves tested this scanner on different machines. and he showed excellent results, now we recommend it to ALL! So that you do not fall for the Chinese fake, we publish here a link to the official site of Autoscanner.

Combustion of fuel in the ICE cylinders is accompanied by the release of a significant amount of heat, only a part of which is used by the engine and is converted into mechanical energy. The rest is uselessly lost, and to neutralize its surplus, you have to use special devices. These include, the ability to work in any conditions provides a cooling radiator fan.

The principle of operation of the radiator fan

Before considering this issue, we will discuss in general what a water-based engine cooling system is, shown below in the figure. He will allow us to recall the principle of her work.

In cases where cold liquid passes through the motor jacket, it takes away excess heat, while the engine cools and the water heats up. Then it passes through a radiator, where it gives off the received heat to the atmosphere, and again enters the motor.

The radiator design is a set of thin tubes that create a large cooling surface. The incoming air stream passing through it takes away the excess heat that is stored in the liquid. In cases where there is no free air flow (engine idling, plugs and other similar situations), or it is not enough to cool the water to the desired temperature, and the cooling radiator fan is provided.

For this, there is a special control circuit, the basis of which is the thermal switch of the radiator fan. It controls the temperature of the liquid. When it exceeds the set limits, the sensor is triggered, at its signal the radiator fan is switched on, which creates the necessary air flow. This stream cools the heated water, and when its temperature assumes the required value, the sensor activates again and turns off the airflow.

This is how you can describe the basic principle by which the radiator fan works - it turns on when the water temperature exceeds the set temperature, and turns off after it drops to the desired value.

What is the risk if the radiator fan does not work

ICE is a complex device, and its characteristics are optimal when it works at a certain temperature. As noted above, it depends on the proper operation of the cooling system. In the case when it is not possible to withstand the desired temperature, the consequences will be quite sad - if it can well jam and then, at least, a major overhaul is provided to him.

The stability of the entire system should create a fan, allowing to reduce the temperature of water in any conditions. But if it does not work, especially when it's hot, then you need to look for why the fan does not turn on or does not spin. Now such devices are usually electric, and the failure of the product itself is unlikely, and a possible reason for this is often the failure of its harness (sensor, fuse, connecting wires, etc.).

So, figuring out the reasons why the radiator cooling fan is constantly working or why it does not turn on or does not spin, it is first of all necessary to check the device binding.

How to check the radiator fan

As we have already established, the radiator fan should turn on when the temperature of the water (antifreeze) exceeds the set value. This can be checked by the readings on the front panel. If the fan does not turn on, then it is necessary to check the entire signal flow chain.

- Check for supply voltage to the product. To do this, you can use a tester or a light bulb. A lack of voltage will indicate a possible blown fuse or poor contact in the wires.

- The health of the fan itself can be checked by applying voltage to it directly from the battery. If it is spinning, then everything is fine with it, and the defect must be sought in other devices. If not, and the fan does not spin, then the cause of the defect is in it. In principle, at the same time you can not stand still and move on, but you must always constantly monitor the temperature of the engine. When the arrow approaches the red sector, you need to stop, open the hood and cool the engine. Two tricks will allow you to move in this case. Keep the speed at least sixty km / h, then the constantly oncoming flow of oncoming air will cool the water passing through the radiator, and you can move in normal mode while maintaining speed. Another technique that allows you to partially replace a non-working fan is to use heating. Turn the stove to the maximum heating mode, in this case, part of the excess heat will go through the heater. True, the cabin will be like in a bath, but you can get to the nearest service station.

- To test the sensor, disconnect the wires from it and close them together. If at the same time the fan turns on and turns, it means that the sensor itself does not work, it cannot be repaired, only replaced. However, if you leave the wires closed, then you can move on, with this option, the fan spins constantly, although it is possible the engine temperature will be lowered, but this is better than standing still.

Radiator fan runs continuously

Such a case is partially considered above, the cause is a temperature sensor failure or short circuit of wires going to the fan. But if it is constantly spinning, then this can also be caused by a sticky relay. This happens quite often, especially after the relay is triggered and the fan should turn on.

The sticking of the relay contacts means that they cannot open, due to which there is a constant supply of voltage to the contacts, as a result of which the electric motor rotates constantly. The consequences of sticking relay contacts include the fact that the radiator fan does not turn off.

Often the reason that the fan does not work is thermostat.. The fact is that the sensor is located in the head of the unit, it determines when the fan should be turned on. But the coolant can move in a large and small circle, when it moves in a small circle, it does not enter the radiator for cooling. The mode of movement of water is determined by the thermostat.

If it is stuck in the position of water movement in a small circle, then it will move and overheat, which will trigger the sensor and turn on the fan, but since water does not enter the radiator, it will not cool, and the sensor will constantly signal a high temperature. As a result of this, the radiator fan does not turn off. This case is determined simply - you need to touch the hoses going to the radiator. When the thermostat is stuck, then with an overheated engine they will be cold.

If the radiator fan does not turn off due to a jammed thermostat, then sometimes you can knock on the case to eliminate this phenomenon. Often this is enough, and the defect disappears. If everything remains unchanged, you will have to remove the thermostat, remove all the stuffing from it and then put the device itself in its place.

Another variant of the same defect will be the jamming of the thermostat in an intermediate position. It can also lead to the fact that the radiator fan does not turn off, but this situation is diagnosed much more difficult. Similar difficulties are caused by the fact that a certain amount of water enters the radiator, but it passes too little, all the water does not have time to cool, which leads to overheating of the engine.

All of the above is not a complete description of the possible reasons why the radiator fan does not turn off. There may be many, sometimes quite strange and unexpected, but in each of these manifestations of malfunctions it is necessary to look for the causes and conduct a thorough analysis.

The radiator fan starts early

Another extreme is when the fan starts early. In this case, you must again look at the temperature sensor. Most likely, it needs to be replaced. Unless, of course, is the right sensor. The fact is that the sensors are designed for different temperatures, they are also called summer and winter, each of them must be included in its own temperature range. The latter are triggered later. And if you used these all the time, then it may seem to you that the fan turns on early, although it is carried out on time and everything works correctly.

We must really appreciate how early everything happens. If early inclusion is established according to indications on a combination of devices, then this is not an indicator. However, when such a switch is disturbing, connect the appropriate equipment through the diagnostic channel and look at the actual sensor thresholds.

Cooling the motor of a car is the most important task. If you allow the engine to overheat, then in the best case it will need a major overhaul. The ability to operate the car in any conditions is ensured by the reliable operation of the cooling system, which is largely determined by the correct operation of all its components.

VAZ 2109 cars are equipped with injection and carburetor engines, each of which has a cooling system. One of the important elements of this system is the fan.

Check

On VAZ 2109 engines, the operating temperature is 90 degrees.

If the pointer arrow crossed the mark of 100 degrees, the car should be stopped immediately, turn off the engine and wait for the power unit to cool. Without doing this, you are facing a major, expensive motor repair.

The motor may overheat for various reasons:

- The thermostat is out of order;

- The radiator is clogged;

- The radiator fan is out of order;

- The fan on sensor has broken;

- The coolant level in the system has fallen;

- The pump is out of order;

- The integrity of the wiring in the fan circuit has been violated.

All these reasons can and should be checked before buying new parts.

Here is an example of checking the fan and sensor.

|

Verification Object |

Method |

|

Fan |

Take one wire about a meter long. Preferably with two crocodiles at the ends. The mass goes to the fan. Your task is to apply voltage directly to the fan from the battery. Apply 12 volts to the second fan terminal. If he spun, everything is fine with him. If not, have to change |

|

Fan sensor |

After turning on the ignition, close the sensor contacts with a screwdriver. Normally, when the fan closes, it should start spinning, and if it is open, then stop. Please note that different types of sensors have a certain response temperature - from 87 to 90 degrees or more |

Do not rush to immediately change the fan. Not infrequently, the problem was in the sensor, relays, fuses, or simply in broken wiring. First of all, check the sensor, and also talk about the features of its replacement.

Signs of a faulty sensor may be a failure to turn on the coolant at high temperature or turn it on on a cold engine.

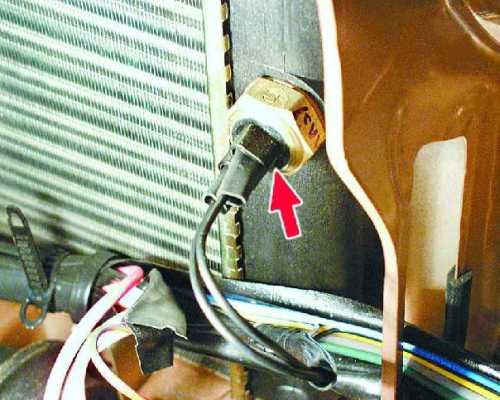

The fan on sensor is located at the bottom of the radiator. A couple of wires depart from it.

Accurate check

In order not to rush to conclusions, experts first advise checking the sensor for operability.

- If the fan does not want to turn on according to the standard scheme, try to close the wires that go to the sensor between each other. If the fan is working and the sensor is hot, the problem lies in it. If the heat sink is hot, the sensor housing may be warm during the test. This suggests that the condition of the thermostat and the coolant level in the tank should be checked. You may have to change and add accordingly.

- If the vent does not turn on after the wires are shorted, the sound of the tripped relay is not observed, check the condition of the relay and fuse. He is number 4 in the mounting block.

- Having closed the wires, the fan did not start, but the relay worked. Here you should check the fuse at number 8.

- If the vent is randomly started on a cold engine, it does not turn off for a long time, try disconnecting one wiring from the sensor. If the fan stops, the sensor contacts are stuck. If the fan continues to turn, sticking occurred at the contacts of the control relay.

Finding out that the regulator is out of order, there is nothing left but to change the sensor for activating the radiator fan.

Sensor Replacement

Changing the sensor is quite simple:

- Turn off the ignition;

- Drain the coolant from the expansion tank;

- Disconnect a pair of wires from the sensor terminal block;

- Using a 30 wrench, unscrew the regulator from its seat. It’s not worth putting a lot of effort, you risk breaking the landing nest;

- Following in the reverse order, install a new sensor.

You can change the sensor without draining the coolant. To do this, quickly unscrew the old regulator and screw in the new one in its place. A small part of the coolant will pour out, but then you will not have to drain it for a long time, and then fill it back.

Fan

If the problem lies in the cooling fan of the injector or carburetor, then you have to remove it. It is possible to repair the unit by replacing the electric motor or the impeller.

To remove the vent, do the following:

- Disconnect the negative terminal from the battery;

- Disunite blocks of wires. One of them is mounted on the fan casing;

- Take a wrench, unscrew a pair of connecting bolts. They fix the vent cover on the left tank;

- Next, unscrew another lower nut holding the device casing;

- Now you need an extension with a cap head to unscrew the right nut on top, which secures the fan casing to the radiator;

- It remains a little - to unscrew the pressure plate of the fan. To do this, remove a pair of left nuts;

- Manually remove the pressure plate;

- Dismantle the fan now with the casing.

You removed the unit. Now you have a choice - to completely change the unit, or try to repair it by replacing the electric motor or the impeller in case of damage.

Replacing an electric motor

- Disconnect the wire of the fan motor, which is held by the clamp on the casing.

- On the casing, the electric motor is held by three nuts. All of them need to be unscrewed.

- Remove the motor from the fan housing.

- Be sure to check the condition of the rubber bushings of the electric motor, which will remain on the casing. If cracks, traces of deformation are detected, they must be replaced.

- Check the electric motor for performance. If it fails, you can purchase a new one and insert it into the old casing.

It is not uncommon for the radiator vent to fail due to a deformed impeller. Replacing it, you can return the functionality to the device.

Impeller replacement

To change the impeller, follow the instructions:

- Pry the lock washer with a flat screwdriver. It is located right in the center of the impeller;

- Pry off the puck, remove it;

- In some cases, the impeller is attached to the fan motor with a nut. Therefore, if you have one, unscrew the mount;

- Remove the impeller, evaluate its condition. If it is worn, deformed, replace with a new one;

- Many instead of a standard 4-blade impeller install a more advanced 8-blade impeller.

During reassembly, make sure that the pin of the electric motor is in the longitudinal hole on the impeller, as shown in the figure below.

Modernization

If you want to improve the performance of your radiator fan on the VAZ 2109, we offer the appropriate instructions.

To upgrade, you will need to install a second sensor and redo the system a bit.

- The standard on sensor will be responsible for the operation of the fan at maximum speed.

- An additional sensor will include a reduced speed. It is installed at the top of the cooling system.

Now more specifically about how to organize all this.

- Take a temperature sensor, the response temperature of which is similar to the standard controller.

- Install it in the upper pipe fitting to the radiator.

- To mount the element, you need a pair of washers and a nut. Be sure to lubricate the washer with sealant so that no leaks occur through the installation opening.

- Buy a resistor to install on the stove fan. He has several conclusions, therefore, if desired, you can make several speeds.

- An additional control circuit must be made. Through it, less voltage will be applied to the motor winding.

- The temperature sensor located in the upper part of the cooling system is responsible for switching on.

- Management is best done not on the plus side, but by weight.

- The system will work through a button in the cabin. To the left of the dash is a grille with two plugs. Cut one of them and set it to turn off in two modes. You can take the controller to turn on the stove from the VAZ 2107.

- In the first position, the low frequency will turn on, and in the second - the maximum speed.

- One common wire is fed to the minus.

Such modernization is not provided for by the design of the VAZ 2109. This is a refinement of motorists. Therefore, the installation of a second sensor is purely at your personal responsibility.

A fan is an important component of the cooling system of injection and carburetor engines of the VAZ 2109. If you want and have the time, it is quite possible to replace or repair it with your own hands.